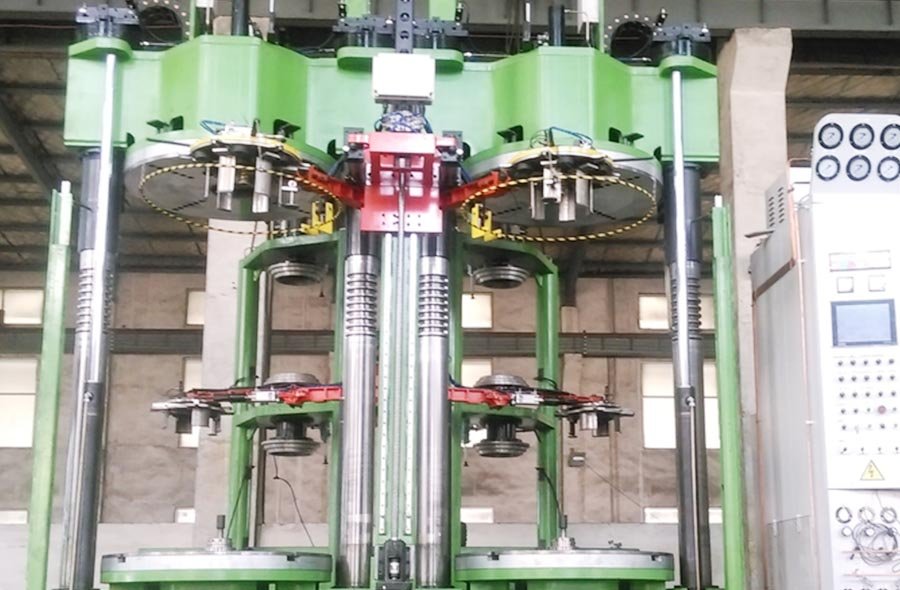

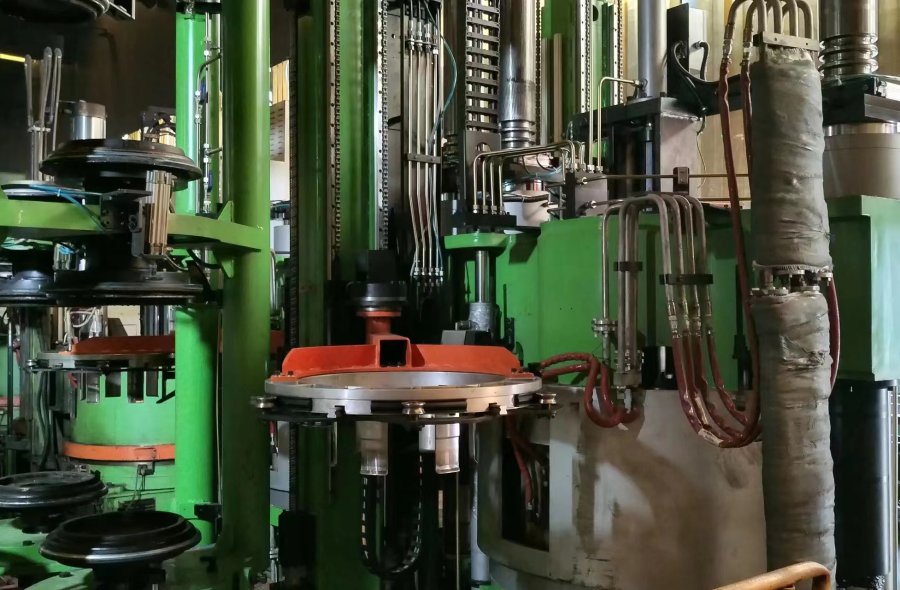

Hydraulic curing press for PCR/TBR/Vulcanizing machine/Tire curing press

Application

Hydraulic curing press for PCR/TBR is high-precision, full-servo controlled tire curing press, to adapt the requirements of intelligent tire factories for high-precision control of tire curing process, such as tire loading, shaping, curing, tire unloading, inflation, cooling and inflation shaping.

Feature

Auxiliary time within 60 seconds, full servo control.

Highlights

1. Automation: PLC control, full automation for the whole curing process.

2. High precision: Full servo control realizes zero error of moving parts.

3. Low energy consumption: integrated pipeline layout, energy saving more than 30%.