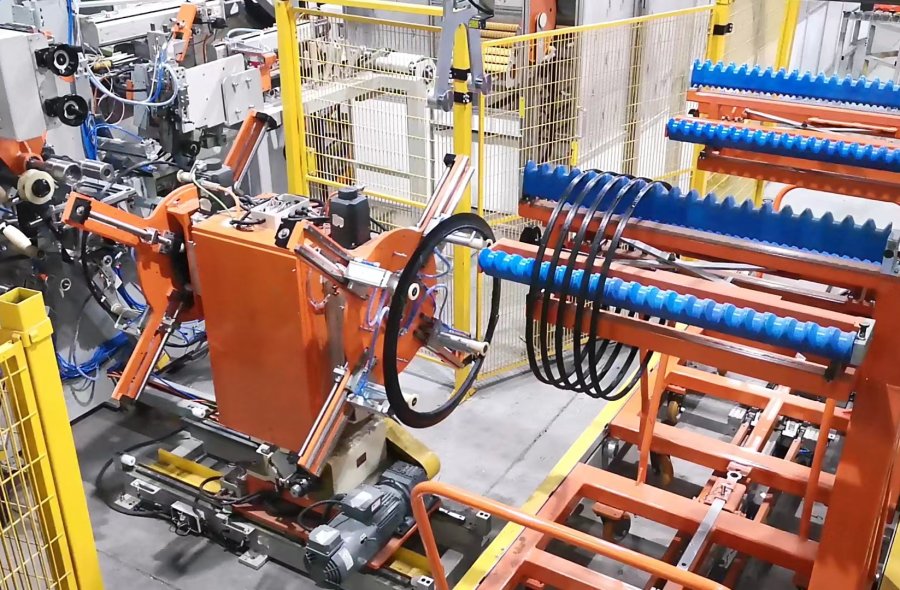

Fully auto apex application(&flipper) production line/Application&flipper line

Application

It's fully integrated system for apex application and flippering on rubberized bead wire. The entire process from apex extrusion, conveying, cooling, storage, application (synchronous action of flipper let-off, application and cutting) to apexed bead collection, storage and trolley transportation is fully automatic. The system is with wide production range, uniform apex application(&flippering) performance for different bead wire size and structure.

Feature

Achieving high quality apex application(&flippering) for multi-specification bead wire through automated constant pressing force.

Highlights

1. Wide production range: Online production for 24"~52" bead wire apexing&flippering.

2. High automation: Intelligent whole line linkage,unmanned operation.

3. Superior quality: Constant pressing force for tight application and even&flat joint, flipper overlap accuracy: ±5mm