1、 Tire factory process tooling:Manufacture according to customer's technology process and drawings.

2、 Valve series: Various kinds of stainless valves

3、 Knife series:Cutters for each process

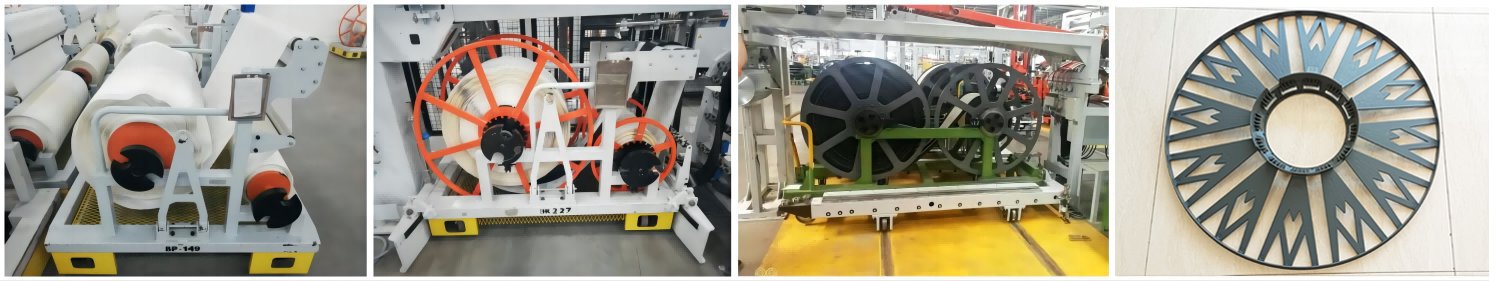

4、 Equipment parts upgrading series:

4.1 Automatic tread pick-up series

Tread Automatic Pick-up Technical Agreement

Video : Automatic tread pick-up series

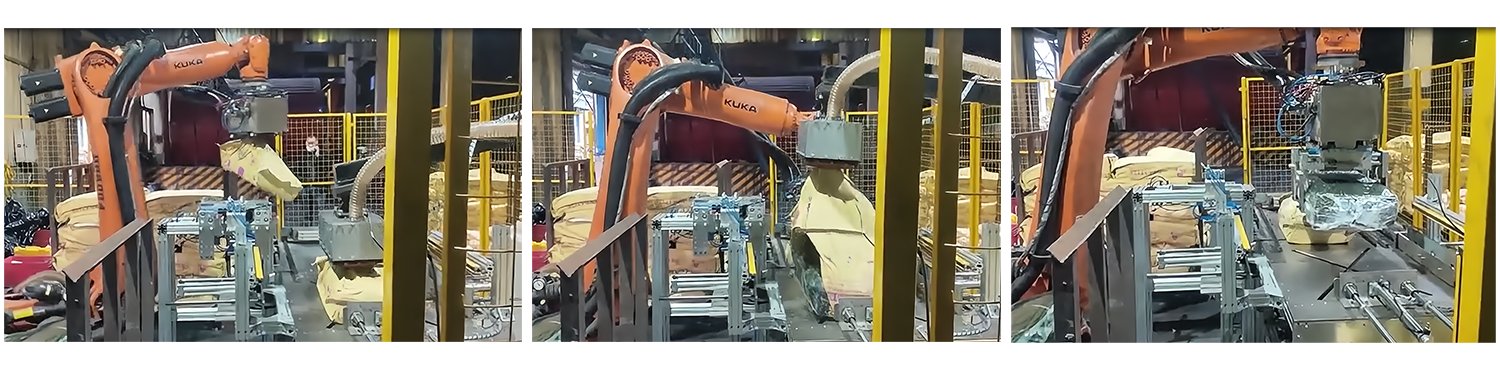

4.2 Automatic synthetic rubber bag unpacking system

The machine is used for plastic bag unpacking of butadiene styrene and butadiene rubber (25 or 35KG) with the characteristics of high production efficiency (6-80 tons of plastic in 12 hours), friendly interface and easy operation.

Video : Automatic synthetic rubber bag unpacking system