Recently, the Shandong Provincial Department of Industry and Information Technology and the Shandong Provincial Branch of the People's Bank of China released the "2024 Shandong Province Enterprise Technical Transformation Key Project Guidance Catalog", the total project investment is 656.16409 billion, with a planned investment of 174.70835 billion in 2024 and a financing requirement of 123.56777 billion.

Among the 1,500 projects, there are 482 high-end transformation projects, 768 intelligent transformation projects, 134 green transformation projects, and 116 industrial base reconstruction projects.

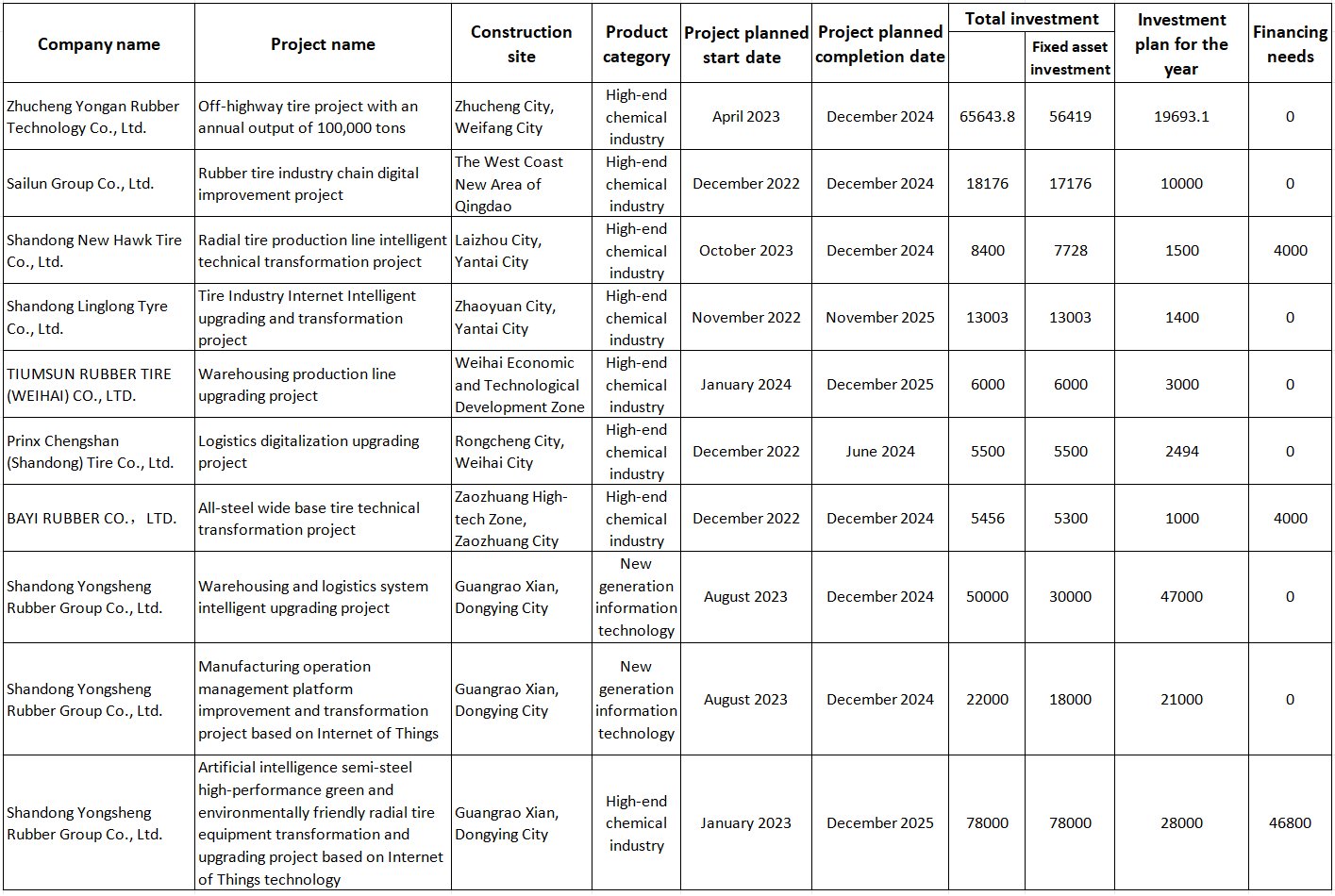

10 major tire projects with a total investment of 2.7 billion

It is understood that among the key technological transformation projects in Shandong in 2024, 10 tire projects will be covered:

Zhucheng Yongan Rubber "Off-highway tire project with an annual output of 100,000 tons".

Sailun Group "Rubber tire industry chain digital improvement project".

Shandong New Hawk Tire "Radial tire production line intelligent technical transformation project".

Shandong Linglong Tyre "Tire Industry Internet Intelligent upgrading and transformation project".

TIUMSUN RUBBER TIRE "Warehousing production line upgrading project".

Prinx Chengshan "Logistics digitalization upgrading project".

BAYI RUBBER "All-steel wide base tire technical transformation project".

Shandong Yongsheng Rubber "Warehousing and logistics system intelligent upgrading project".

Shandong Yongsheng Rubber "Manufacturing operation management platform improvement and transformation project based on Internet of Things".

Shandong Yongsheng Rubber "Artificial intelligence semi-steel high-performance green and environmentally friendly radial tire equipment transformation and upgrading project based on Internet of Things technology".

According to statistics, the total investment in this tire technical transformation project is 2.721788 billion yuan, including 2.37126 billion yuan in fixed assets investment, and the planned investment in 2024 is 1.350871 billion yuan.

According to the notice, this batch of key technological transformation projects are selected projects with high quality and efficiency, strong innovation capabilities, good development prospects, and sufficient traction.

The notice requires that all municipal industry and information technology departments must implement "list-based management and responsible promotion", reverse the construction schedule, and fight against wall charts, and make every effort to accelerate the implementation of key provincial technical transformation projects in 2024.

It also requires all financial institutions to optimize the approval process to meet the financing needs of enterprises for technological transformation projects to the greatest extent, and ensure that all loans are available as quickly as possible.

Shandong Tire, accelerating quality improvement and upgrading

In recent years, Shandong tire has resolutely eliminated backward tire production capacity, actively promoted industrial upgrading, and helped Shandong tire get rid of its "low-end OEM" image.

At a press conference held by the Shandong Provincial Government in December 2023, the Shandong Provincial Department of Industry and Information Technology revealed that the development of Shandong's tire industry has made a huge breakthrough. It not only successfully reduced, transferred and integrated 23.8 million tires, but also implemented a production capacity expansion plan. The overall tire production capacity exceeds 70 million units, showing the high-quality development momentum of the industry.

It is understood that new expansion and technological transformation projects also need to comply with a series of environmental policies, including no longer implementing production capacity, energy consumption, and carbon emission substitution policies. They also need to use clean energy and are not allowed to use traditional energy sources such as coal. These policies aim to ensure that new production capacity projects have higher environmental standards to reduce adverse impacts on the environment.

It can be said that the Shandong tire industry has made significant progress through capacity expansion and the implementation of environmental protection policies after eliminating backward production capacity. This shows that Shandong's tire industry is moving towards high-quality development and has made a positive contribution to the rise of China's tire industry.

The implementation of a new batch of tire technical transformation and improvement projects in 2024 will further improve manufacturing levels, and more green and low-carbon projects will help Shandong Tire move to a new level of high-quality development.

DLFTECH is a professional equipment service company established by a senior marketing and R&D team in tire and rubber conveyor belt equipment industry. Leading by automation process equipment demand, the company is committed to the docking of intelligent equipment and technology, to achieve zero distance technique process and bring new profit growth points and continuous market competitiveness to customers. Select DLFTECH, so you have the best solution, always!

If any tire or conveyor belt industry customers need such as rubber track curing press, tire mold intelligent laser cleaning system, hydraulic curing press for PCR/TBR, etc., please feel free to contact info@delphygroup.com.