In the past two years, domestic tires have set off an investment boom in China. Domestically, many tens of billions of large-scale projects are planned to be implemented. While domestic brands are making rapid progress, what measures are foreign brands taking in mainland China?

In fact, although the sales and production capacity of foreign-owned truck and bus tires are indeed declining in China, passenger tires are not showing signs of timidity. In the past year, many foreign brands have announced plans to build factories and expand in mainland China.

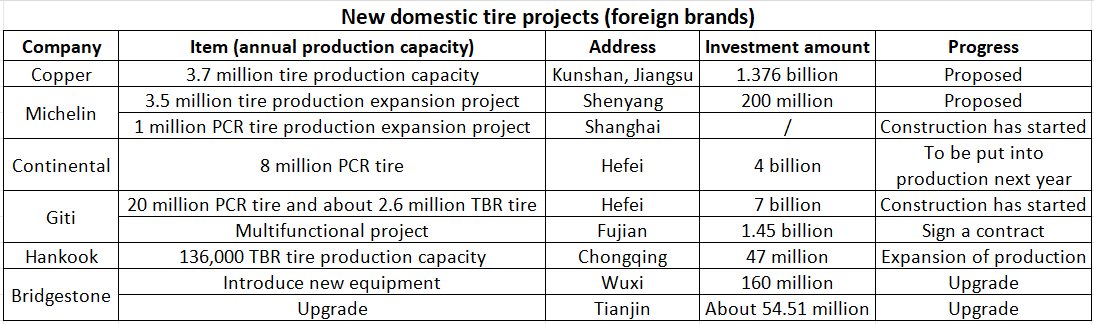

The above figure is not a complete statistics. Currently, there are 8 projects planned to be built or have already started construction such as Michelin, Goodyear, Continental, etc., with a total production capacity exceeds nearly 40 million units, mainly for passenger tires. The specific project plan is as follows:

Cooper Tire lays foundation for annual production of 2.6 million tires

In 2023, Goodyear's Cooper Tire factory in Kunshan, Jiangsu Province announced an expansion, involving a total new investment of US$200 million.

Cooper Tire's expansion plan is divided into two parts. The original production line of the Kunshan factory will be expanded to increase the production capacity of 1.1 million tires; at the same time, the production capacity of 2.6 million tires will be added.

On May 31, 2023, the second phase of the Cooper (Kunshan) project with a total investment of US$200 million started laying the groundwork in the Kunshan Development Zone. After completion, the annual output of high-performance radial PCR tires will be 2.6 million, and the company's annual total output value is expected to exceed 2 billion yuan.

Michelin Shenyang and Shanghai factories expanded

In June 2023, the environmental impact report form of the post-processing project (major changes) of Michelin Shenyang Tire Co., Ltd. was made public.

This project, with a total investment of approximately 110 million in technical transformation projects, will build 5 million annual silent tire production lines and 700,000 annual self-sealing tire production lines. The annual production capacity will increase by 3.5 million, with the total production capacity reaching 5.7 million.

In addition, in November 2023, the second phase of the Michelin Shanghai factory reconstruction and expansion project started laying the foundation. The second phase of the project plans to further expand the production capacity of high-performance and high-value radial passenger tires in stages based on the first phase. The project is expected to be completed before the end of 2026, when the annual production capacity will be increased from 8.5 million to 9.5 million.

Continental Hefei's 8 million tires are about to be put into production

According to local media reports in November 2023, the production equipment for the fourth phase of the Hefei factory of Continental Tire has been gradually put into production and will be gradually put into production in the first quarter of 2024.

The fourth phase of the Hefei factory of Continental Tire was start construction in October 2022. It can produce 8 million passenger car radial tires annually, including 600,000 self-repairing tires and 400,000 silent tires.

After the completion of the construction of the fourth phase of the project, the overall annual production capacity of Continental Tire's Hefei plant will reach an astonishing 21.5 million passenger tires, 600,000 self-repairing tires and 400,000 silent tires. The factory will also add an annual production capacity of 15 million cycle tires.

Bridgestone's two major passenger tire plants receive investment

While truck and bus tires are slowly retreating, Bridgestone is making every effort to promote investment in the passenger tire business.

In 2024, Bridgestone plans to upgrade its tire manufacturing plant in Wuxi, Jiangsu, investing RMB 160 million to add a new internal mixer and replace 32 curing presses.

In addition, in December 2023, Bridgestone announced that it would upgrade its tire production facilities in Tianjin, China. The project, with an investment of 7 million euros, has been launched and includes replacing the "triplex extruder" with advanced "quaduplex extruder" technology by mid-2025.

DLFTECH is a professional equipment service company established by a senior marketing and R&D team in tire and rubber conveyor belt equipment industry. Leading by automation process equipment demand, the company is committed to the docking of intelligent equipment and technology, to achieve zero distance technique process and bring new profit growth points and continuous market competitiveness to customers. Select DLFTECH, so you have the best solution, always!

If any tire or conveyor belt industry customers need such as rubber track curing press, tire mold intelligent laser cleaning system, hydraulic curing press for PCR/TBR, auto bead apex line, etc., please feel free to contact info@delphygroup.com.